- My account

-

Cart is empty.

Environmental strategy

The protection of our environment for future generations.

We are aware of the important role of protecting our environment for future generations. To maintain this environmental strategy, we apply a set of activities that allow the company to achieve its goals minimizing its negative impact on the social and environmental setting.

Optimization of the production process.

Optimal management of efficiency, quality and costs in production processes.

The production is planned under the energy optimization criteria and carrying out a periodic control of consumption.

Intelligent manufacturing that starts from quality at the beginning , takes advantage of resources, minimizes manufacturing defects and downtime and achieves cost savings.

Comprehensive waste management plan

The company has a comprehensive waste management plan. It also performs a previous classification of waste and it has the help of the services of an approved company that ensures a recovery circuit for the waste generated.

The wood

The wood remains are transported to recovery plants where chipboard panels are manufactured.

The metals

The metals are transported to iron and steel foundries for the subsequent manufacture of moulding parts.

The plastics

Plastics are transported to manufacturing plants where new products will be made.

The imitation leather

The scraps that cannot be used as raw material are donated to other companies for the manufacturing of textile products.

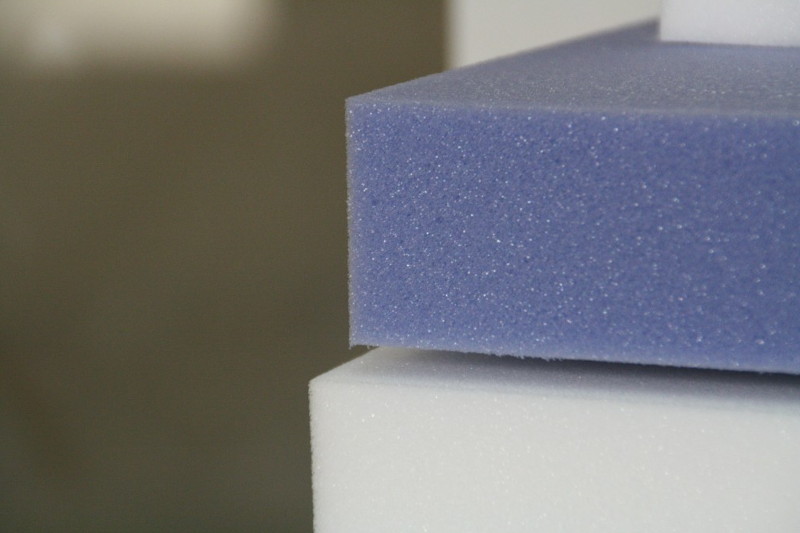

The foam

Our foams are free of harmful additives for their recycling, so scraps and trimmings can be reused in agglomerated products after specific manufacturing methods.

Product design

Products are designed with environmentally friendly materials

The manufacture of our products is based on a methodology based on ecodesign where environmental criteria play a fundamental role throughout the entire life cycle. We minimize the environmental impact in its design and we continue the analysis in its own production, use and even in its withdrawal.

During the design phase, we prioritize the use of recycled and / or recyclable materials (steel, wood and plastics) without neglecting the safety and usefulness of our products.

- The wood used in our products comes from sustainably managed forests recognized by the FSC and / or PEFC Forest Certification System.

- The imitation leather is manufactured following the standards of the ISO 14001: 2004 Environmental management systems.

In the manufacturing stage, we continuously identify the possible environmental aspects and impacts of the product based on the continuous improvement process which allows us to make decisions aimed at minimizing its impact on the environment.